Customized High Temperature Resistant Peek Rod Anti Static Zero Cut Sheet

Basic Info.

| Model NO. | plastic peek sheet |

| Density | 1.5g/cm3 |

| Free Sample | Available |

| Transport Package | Plastic Bags, Pallet, Wooden Case, Container |

| Specification | OD)30-800X (ID)20-600X length(500-1000mm) |

| Trademark | GZ-Engineering Plastic |

| Origin | Guangdong, China (Mainland) |

| HS Code | 3907400000 |

| Production Capacity | 10000PCS/Month |

Product Description

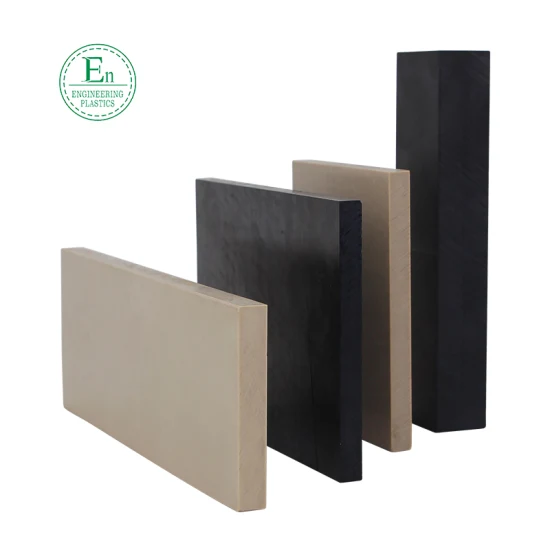

CNC lathe milling service hard plastic board PEEK sheet custom processing plus fiber PEEK anti static plastic sheetHigh Performance plastic peek sheet

Features

PEEK is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good mechanical properties and chemical resistance, abrasion resistance, and hydrolysis resistance properties etc.; it has a light proportion and self-lubricating properties. Due to very good processing properties, it can be filled with carbon fiber and MoS2 etc. to improve lubrication performance and mechanical strength further.

Main Characteristics of Peek

•Very good sliding properties even without lubrication

•Good thermal mechanical bearing strength

•Good chemical and hydrolysis resistance even against superheated steam

•Very wear resistant

•Very rigid

•Creep resistant

•Not electrically insulating

•Good machinability

•Resistant to gamma radiation

•Self extinguishing V-0

Special properties of PEEKBesides, PEEK can be used to produce some exact medical equipments for the OPS and dentistry, which can annihilate bacterium and can be used time after time, the most important application of PEEK, which is used to produce the artificial bone instead ofmetal. The artificial bone, which is made of PEEK, has the good performance of light-weight, non-toxic and good-chemical-resistance and so on, and can integrate with the organism of human body. So PEEK is also successfully applied in medical industries.Regular sizeColor:Natural,Black,Khaki and so on.PEEKSheet Size:500X1000X(Thickness:1-100mm)600X1200X(Thickness:1-100mm)PEEKRod Size: Φ6-Φ200X1000mmPEEKTube Size:(OD)30-600X (ID)20-500X length(500-1000mm)

The parameter list of peek sheet

| Model | Plastic peek sheet |

| Material | PEEK,PPS,PI or customized |

| Thickness | 3-100mm or customized |

| Length | 500-1000mm or customized |

| Color | Natural,amber,etc. |

| OEM & ODM | Yes |

| Certification | ISO9001,SGS,FDA,RoHS,Test Report,ect. |

| Free Sample | Yes |

| Density | 1.5g/cm3 |

| Shape | sheet, rod, tube, gear, pulley, guide rail......or according to your drawing |

| Packing | Plastic bags,Cartons,Wodden case,Pallet,Container,ect. |

| Advantage | 1.One stop procurement 2.A complete range of specification 3.free design offer OEM & ODM 4.free sample available 5.professional service team 6.specialize CNC machining and injection over 10 years 7.Custom accept as per drawing or sample |

| Property | Item No. | Unit | PEEK-1000 | PEEK-CA30 | PEEK-GF30 | |

| Mechanical Properties | 1 | Density | g/cm3 | 1.31 | 1.41 | 1.51 |

| 2 | Water absorption(23ºC in air) | % | 0.20 | 0.14 | 0.14 | |

| 3 | Tensile strength | MPa | 110 | 130 | 90 | |

| 4 | Tensile strain at break | % | 20 | 5 | 5 | |

| 5 | Compressive stress(at 2%nominal strain) | MPa | 57 | 97 | 81 | |

| 6 | Charpy impact strength (unnotched) | KJ/m2 | No break | 35 | 35 | |

| 7 | Charpy impact strength (notched) | KJ/m2 | 3.5 | 4 | 4 | |

| 8 | Tensile modulus of elasticity | MPa | 4400 | 7700 | 6300 | |

| 9 | Ball indentation hardness | N/mm2 | 230 | 325 | 270 | |

| 10 | Rockwell hardness | - | M105 | M102 | M99 | |

Our Factory

Our factory has 100 sets of precision processing equipment, welcome to visit our factory!

One-stop ServiceOEM, ODM, Customization service,Reasonable and competitive price,Design for Manufacturability (DFM) analysis with every quote,Short Delivery Time.

Reliable mold expert 15+ years' experience, Cooperated with many world famous brands for many years, Specialize in large and complex injection mold making, One-stop service from design to production.

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.Professional team

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

Client Witness

Our Exhibition & CCTV Interview

Buying Instructions

Q1. Can samples be produced?A1. YesQ2. What is the accuracy of the products processed by the drawings?A2. Different equipment has different accuracy, generally between 0.05-0.1Q3. What craftsmanship do you have for processing accessories?A3. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.Q4. What are your processing equipment?A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, moldingmachineQ5. Can you help assembling the product after it is made?A5. It's okayQ6. What certifications or qualifications does your company have?A6. Our company's certificates are: ISO, ROHS, product patent certificates, etc.Q7. Can injection products be surface treated? What are the surface treatments?A7. It is ok. Surface treatment: spray paint, silk screen, electroplating, etc.