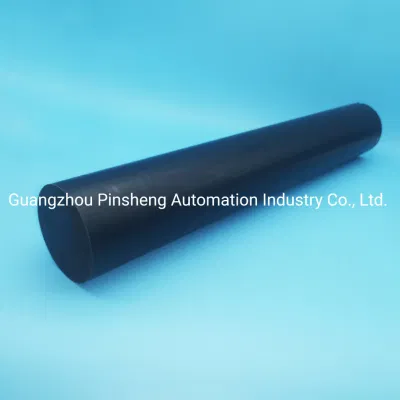

Filling Machinery Nylon Screw Rod for Plastic Screw Bottle Feeding Propeller

Basic Info.

| Model NO. | Plastic Part-JYNR001 |

| Supplying Capacity | One Million Pieces/ Month |

| Tolerance | Generally±0.05mm or Better |

| Production Ways | Injection Molding |

| Surface Finish | Anodizing, Heat Treatment, Polishing, Sand Blastin |

| Process Combination | Progressive Die, Single-Process Mode, Compound Die |

| Lead Time | 15 Days for Molding, 15-20 Days for Series Product |

| Dimension | Standard Sizes or as Per Customers′ Requirement |

| Free Samples | Available |

| Service | Custom Made or OEM and ODM |

| More Materials | ABS, PVC, PA, PU, PBT, POM, PP, Pet, PE, PS, PC or |

| Material Report | FDA, RoHS, UL, and Reach Certified |

| Part Name | Plastic Parts |

| Transport Package | Polybag, Box, Pallet |

| Specification | 100% new resin |

| Trademark | OEM, ODM, Private Label |

| Origin | China |

| HS Code | 3926901000 |

| Production Capacity | 1000000 Pieces/Month |

Product Description

1. Well Shape Keeping2. Deburr, Sharp Edge and Flash3. Precision Tolerance Control4. Nice Surface Treatment5. Colorful Choice

Why Us:

We have a fully-equipped workshop that meets ISO 9001:2015 and IATF 16949:2016 requirements. All products are compliantwith FDA, WRAS, UL, RoHS and REACH standards, and meet DIN, JIS and ASTM regulations. Material report and dimensionchecking report are available.1. Quality Approvals. More than 15 years professional manufacture experience.2. Experienced Staff and Service. Professional R&D team, production team, sales team, after-sales service team.3. Product Performance and affordable cost. Superior performance with most competitive price.4. Prompt Delivery. Faster delivery time. 5. Small Orders Accepted.

| Material | ABS,ASA,PP,PA,PC,PE,POM,HDPE,TPE,TPU, PVC,PBT etc |

| Material Report | FDA, ROHS, UL, WRAS and REACH |

| Dimension | Standard Sizes or As per customers' Requirement |

| Certifications | ISO9001,IATF16949,ISO14001 |

| Color | Any colors according to PANTONE or RAL |

| Surface Finish | Texture (VDI/MT standard, or made to client's sample), polished (high polish, mirror polish), smooth, painting, powder coating, printing, electroplating etc. |

| Service | Custom Made or OEM and ODM |

| Free Samples | Okay |

| Production Ways | CAD Drawing, 3D Files or Samples |

| Production Capacity | 200T,300T and 500T Compressing Molding, Injection Molding, Auto Vacuum Vulcanizing, Plastic Injection, and Extrusion |

| Supplying Capacity | One Million Pieces/ Month |

| Tolerance | Generally±0.05mm or Better |

| QC | PPAP, In House Control, Third Party Inspection Institution such SGS, TUV |

| Lead Time | 15 Days for Molding, 15-20 Days for Series Production |

| Application | Industry Machinery,Automotive,Mechanical Equipment, Construction, House Application,Medical Machine |

| More Parts | Grommet, sleeve, feet, gasket, wheel, bellow, cap, dust cover, pad, washer, Strip, plug, stopper, grip, seal, bushing, bumper, blocks, and anti vibration mounts etc. |

FAQ

1. What types of rubber do you use?

Jinyuan Rubber has extensive experience in a vast range of rubber, including: Natural Rubber, SBR, CR, NBR, HNBR,

EPDM, Silicone Rubber, FPM, ACM, FK etc.

2. What types of plastic do you use?

Jinyuan Rubber has extensive experience in a vast range of plastics, including: ABS, Polypropylene (PP), PVC, POM,

PE, PEEK, Polyamide (PA) Nylons, PBT, etc.

3. What services do you provide?

We offer a broad range of services, including, Custom Rubber Molding, Liquid Injection Molding, Rubber Extrusion, and

Rubber/Plastic to Metal Bonded Parts.

4. Why us?

4.1 More than 15 years professional manufacture experience.

4.2 Professional R&D team, production team, sales team, after-sales service team.

4.3 Superior performance with most competitive price.

4.4 Faster delivery time.

5. Perfect quality control process

5.1 Raw material inspection

All raw materials before warehousing must be tested, and the corresponding physical property report shall be issued,

and compared with the physical property report of raw materials. Only when the test values of the two physical property

reports are consistent, can they be warehoused.

5.2 Mold inspection

After mold development or cleaning, we will check the full size of the mold to ensure that the quality of each cavity is

the same.

5.3 Product inspection

In the process of product production, inspectors regularly inspect the semi-finished products to ensure the rationality

of the process and control the defective rate within a reasonable range.

5.4 Finished product inspection

The double inspection can ensure that the product appearance and size are 100% qualified.